1- Contracting:

A representative from our company collects information about the project, including the approximate area, the required work to be carried out, and the intended use of the project. The Contract Manager then provides a detailed estimate for the project, outlining everything that will be done from the initial land acquisition to the completion of the project, along with the company's specified prices. A specified period is given for responding to the offer. Upon approval of the submitted offer, a contract is drawn up, which includes the estimate and specifies the payment terms and the project's completion timeline. The contract is then signed by both parties.

2. Taking Actual Measurements for the Project

After the contract is finalized, the specialized surveying team takes the actual measurements of the project using a Total Station device with the highest accuracy.

3. Engineering Design Phase of the Project

After taking the actual measurements of the project, the company's engineering department creates the designs and engineering drawings using the calculation notebook. This ensures an accurate project design without excess or deficiency in materials and engineering sections.

4. Manufacturing and Production Phase Inside the Factory Hall

After completing and reviewing the designs, the engineering office hands them over to the production manager to begin the manufacturing process.

The stages are as follows:

A. Cutting, Slicing, and Accessories Preparation Stage:

The sheet metal is sliced, cut, and drilled according to the dimensions provided in the design using plasma and laser machines, and cutting lines. This is done with high quality and precision according to industry standards.

B. Assembly Stage:

The specialized team assembles the sections that have been cut on the automated assembly lines, according to the specific dimensions of each section, with exceptional precision.

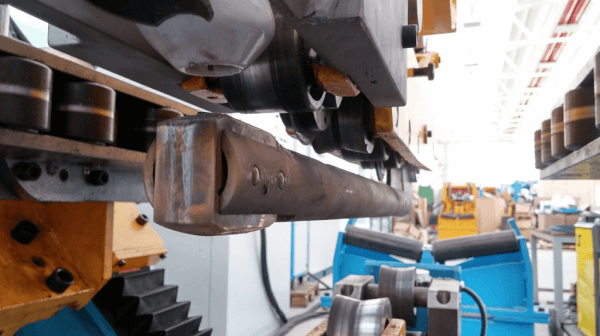

C. Automated Welding Stage:

After assembling the sections on the automated assembly lines, they are then transferred to the automated welding lines, where they are welded with excellent quality and precision.

D. Manufacturing and Assembling Accessories Stage:

After the automated welding stage, the sections are transferred to the manufacturing hall where the specialized team assembles the necessary accessories specified in the drawings and designs, following industry standards.

E. Cleaning, Sandblasting, and Painting Stage:

The sections are cleaned of burrs and other residues using a grinder or sandblasting (if necessary). They are then transferred to the painting department, where they are coated with a high-quality red primer, followed by a high-quality lacquer or epoxy coat (if necessary).

F. Transportation and Installation Stage:

The truss is transported from the factory to the site for installation and distributed to its designated locations. The installation department then raises the truss using the company's cranes, with a dedicated supervisor overseeing the installation team on site.

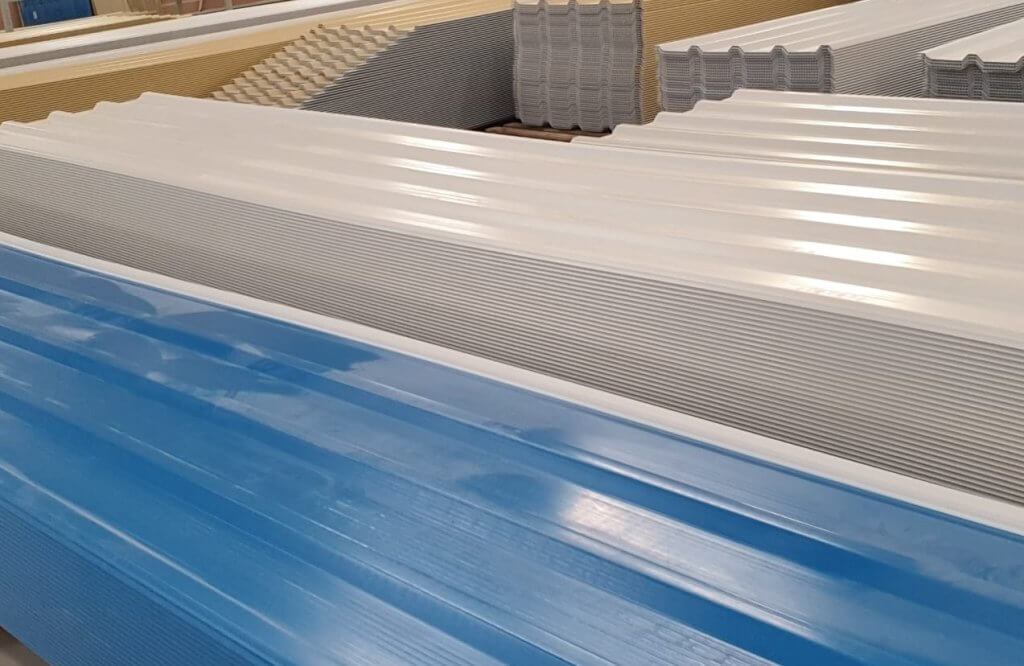

G. Covering Stage:

During the frame installation process, the sheet metal department prepares and cuts the metal sheets or UPVC panels to the required dimensions for the project in our factories. Once the frame installation is complete, the sheets or panels are transported to the site at the required dimensions and lifted onto the truss using the crane. The installation team then secures them with specially designed screws, ensuring the highest quality and best precision.

H. Delivery Stage:

Our quality manager delivers the site after finishing all work and reviewing everything agreed upon in the contract between both parties.